DSI Industrial Automation >>

Industrial Automation That’s Designed, Built, and Commissioned Right

When automation systems fail, it’s rarely the software alone. It’s poor coordination between design, panels, electrical installation, and field execution. DSI delivers industrial automation the way it should be done—fully integrated, thoughtfully engineered, and supported by experienced automation professionals who understand the entire system from sensor to SCADA.

From concept through commissioning, our automation team works side-by-side with DSI’s electrical, fabrication, panel shop, and field crews to deliver reliable control systems that reduce downtime, improve uptime, and scale with your operation.

Automation That Wasn’t Built to Last

Many industrial automation systems are designed for today, not for expansion, modernization, or long-term reliability. Operators and producers often inherit systems that:

-

Lack room for future expansion

-

Require costly one-time upgrades instead of incremental improvements

-

Depend on multiple vendors who don’t communicate

-

Break down when experienced personnel leave

When automation isn’t designed with the full lifecycle in mind, the result is downtime, inefficiency, and expensive rework.

An Automation Team That Understands the Entire System

DSI’s automation group isn’t siloed, and that’s by design.

Our automation engineers work daily with:

-

Electrical construction teams

-

UL-certified panel shop technicians

-

In-house fabrication

-

Field electricians and commissioning crews

Automation acts as the central hub, connecting every discipline into a single, coordinated solution. This integrated approach allows problems to be solved faster, systems to be commissioned more efficiently, and projects to be completed without finger-pointing.

As Dave Thompson, Automation Manager at DSI, explains:

“Automation is kind of that central hub. We design the panels with the panel shop, coordinate with fabrication, and support electricians in the field. We rely on each other and it works really well.”

A Proven Automation Process Built for Reliability

1. Design with the Future in Mind

We design automation systems that allow for expansion, upgrades, and new technology, without forcing a complete overhaul later.

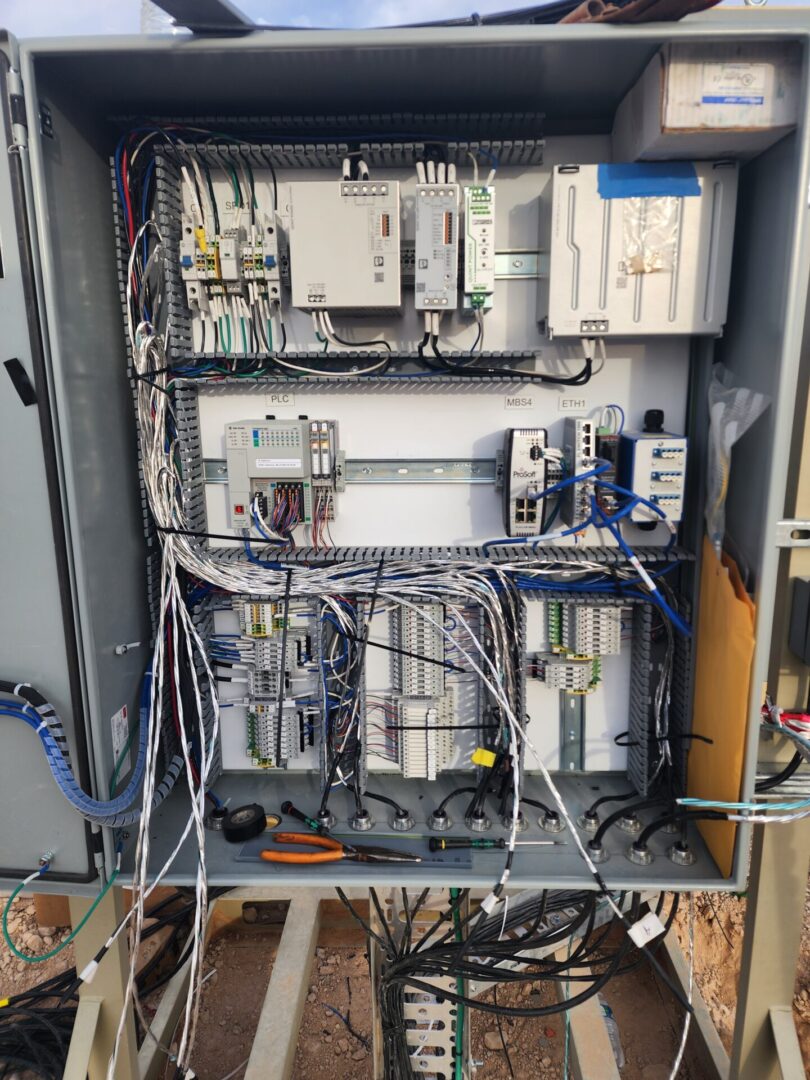

2. Integrated Panel & Electrical Coordination

Automation engineers work directly with DSI’s panel shop and electrical teams to ensure controls, wiring, and layouts are built exactly as designed.

3. Thorough Testing & Commissioning

Cause-and-effect documentation, pre-commission testing, and structured checkout processes reduce guesswork in the field and accelerate startup.

4. Long-Term Support

DSI doesn’t apply band-aids. If something isn’t right, we fix it, because our reputation is tied to how the system performs long after startup.

Comprehensive Industrial Automation Capabilities

DSI provides full-scope industrial automation services, including:

-

PLC Programming & System Design

-

HMI & Operator Interface Development

-

SCADA Systems & Reporting

-

Data Acquisition & Alarm Management

-

Instrumentation Testing, Calibration & Troubleshooting

-

Automation Expansion & Modernization

-

Panel Design & Electrical Schematics

-

Network & Communications Integration

-

Motor Control & VFD Programming, Startup & Optimization

Our automation team is experienced across oil & gas, industrial processing, municipal systems, and complex field environments—bringing real-world perspective to every solution.

Integrators, Not Just Programmers

At DSI, automation engineers are integrators first.

That means one person can:

-

Terminate devices

-

Troubleshoot instrumentation

-

Program PLCs and HMIs

-

Support commissioning in the field

This approach eliminates the inefficiencies of multi-vendor, multi-role automation models, reducing labor, miscommunication, and delays. In some cases, one DSI automation professional can accomplish what takes multiple outside specialists.

Higher Uptime. Faster Commissioning. Fewer Surprises.

DSI’s disciplined automation approach has helped customers:

-

Increase uptime in field operations

-

Reduce commissioning time through structured testing

-

Improve system reliability with better logic, documentation, and design

-

Prepare for future technologies like predictive maintenance and AI-driven diagnostics

Automation done right doesn’t just control equipment, it protects production.

Ready for What’s Next

DSI actively designs automation systems that support:

-

Advanced analytics and predictive maintenance

-

AI-assisted diagnostics

-

Modern SCADA and reporting platforms

-

Scalable architectures for evolving operations

Our goal is not just to meet today’s requirements, but to ensure your automation system remains relevant and reliable for years to come.

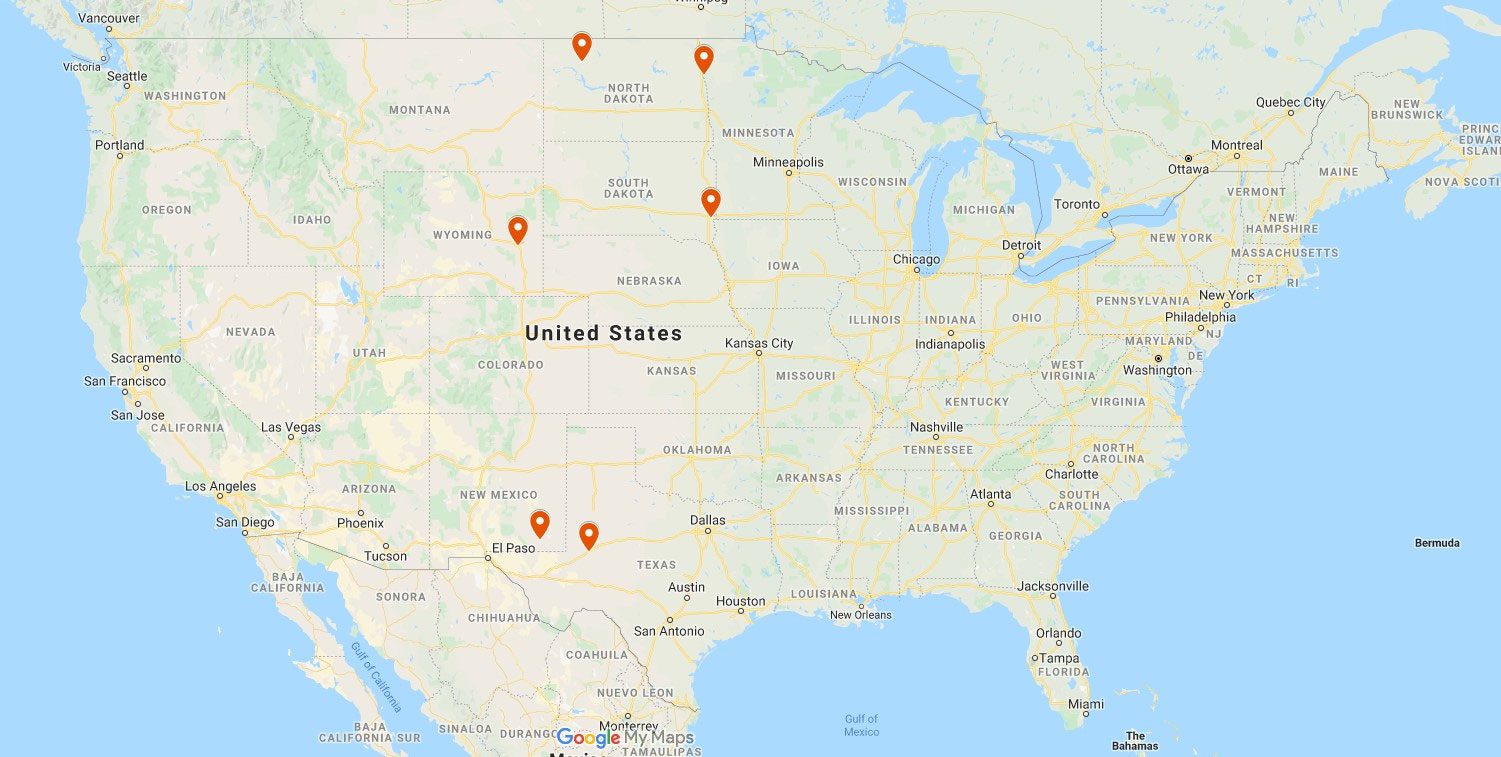

Where We Work

Permian Basin – Midland/Odessa

Supporting oilfield producers across West Texas and southeastern New Mexico.

Williston Basin – North Dakota & Eastern Montana

Providing electrical services for major operators across the Bakken.

DSI is strategically positioned in both regions to deliver fast mobilization and consistent workforce support.

Across The US

Our team travels well and we have teams working in many other areas of the US as projects arise.

Automation You Can Trust From Concept to Completion

DSI delivers industrial automation backed by experience, accountability, and true integration across electrical, fabrication, panel shop, and field services.

If you’re ready to upgrade, expand, or modernize your automation systems, with a partner who does it right the first time—we’re ready to help.

A Partner Committed to Long-Term Reliability

100% employee-owned. Vertically integrated. Deeply experienced across the most active oilfields in the U.S.

DSI isn’t just an industrial automation contractor, we’re a team of craftspeople advancing what’s possible in oilfield and industrial environments.

Let’s Build Something That Works. Every Time.

Your operation depends on electrical systems that perform in real-world oilfield conditions.

Our team is ready to design, install, and support electrical infrastructure that keeps production moving.