DSI UL Certified PANEL SHOP >>

UL Certified Panel Shop Delivering Field-Ready, High-Reliability Control Panels

From concept to completion, DSI builds UL-certified control panels engineered for extreme environments, oilfield automation, municipal systems, and industrial operations.

When Your Operations Depend on Control Panels, Failure Is Not an Option

In oilfields, industrial plants, and municipal systems, control panels are the brain of your operation. But poorly built or non-certified panels can cause:

-

Unexpected downtime

-

Costly troubleshooting

-

Field installation delays

-

Safety hazards in hazardous locations

-

Documentation gaps during audits or inspections

DSI understands what’s at stake. Your systems must work every time, in every condition, and must be certified to meet strict UL guidelines.

You shouldn’t have to wonder whether your panel builder follows the rigorous standards your industry demands.

DSI: Your UL Certified Panel Shop with 25+ Years of Industrial Experience

Our UL certified panel shop builds UL508A and UL698A industrial control panels for oil and gas producers, municipal water systems, and other demanding applications.

DSI’s panel shop is led by experienced technicians and supervisors who maintain strict compliance with UL requirements, ensuring every panel meets or exceeds certification standards.

As Panel Shop Manager Rob Huling explains:

“We build certified UL panels, 508A and 698A. Every component must be UL listed or recognized, and every wire must be labeled to a T. Our UL inspectors make periodic stops, so we’re always ready.”

WHAT YOU GET WITH DSI

The Strength of a UL Certified Panel Shop, Backed by Full Engineering & Field Services

DSI isn't just a panel shop. We offer design, fabrication, automation, electrical construction, and field installation under one roof, eliminating delays and miscommunication.

Rob explains why this matters:

“When you have engineering, panel building, and fabrication tied together, you’re not waiting on other people. There are fewer surprises, and we can see everything happening in real time.”

With DSI, you get:

-

Engineering expertise (UL, hazardous locations, spacing requirements, heat load, documentation)

-

Panel shop technicians who follow strict schematics and UL guidelines

-

Field services that install and integrate the panels they helped build

-

Automation engineers who program and test the full system

-

Shop-floor leadership ensuring consistency, quality, and workmanship

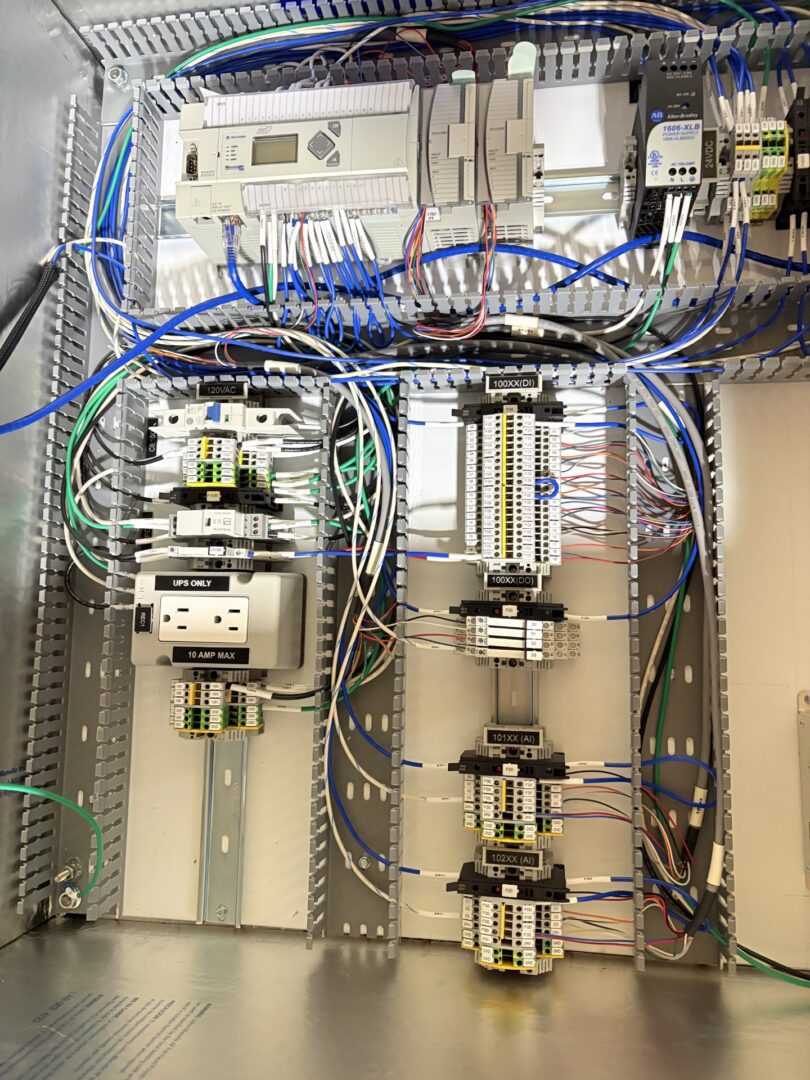

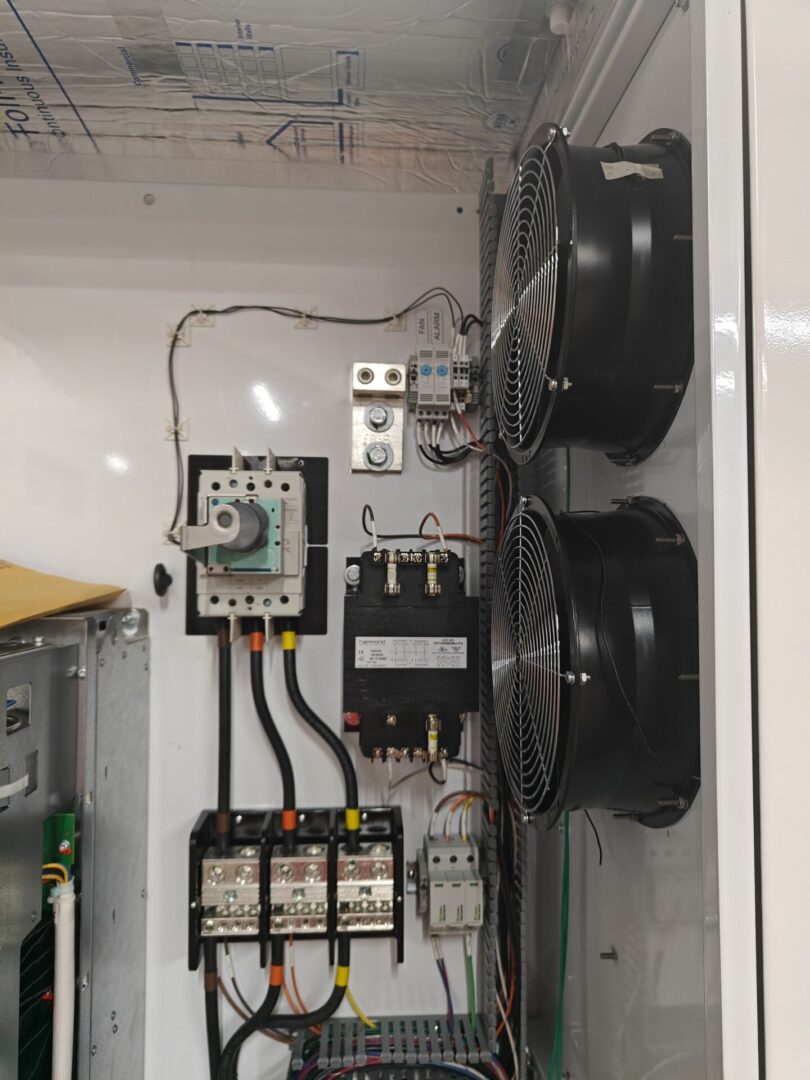

HOW WE BUILD PANELS

The DSI Panel Shop Process: Built Right, Tested Right, Shipped Right

A clear, proven process ensures reliability from design to installation.

As a UL Certified Panel Shop, DSI builds control panels designed for real-world industrial environments where safety, consistency, and reliability matter. Each project begins with close coordination between our engineering, automation, and field teams to ensure every panel meets application requirements, industry standards, and UL certification criteria.

Our experienced panel shop technicians follow documented build practices, detailed inspections, and strict quality controls throughout the assembly process. Before shipment, every panel is fully tested to verify performance, safety, and compliance—reducing startup issues and risk in the field.

This disciplined, standards-driven approach ensures every panel ships ready for installation and reflects DSI’s commitment to quality, accountability, and long-term performance.

1. Design & Component Planning

-

All components must be UL listed or recognized.

-

Layouts follow precise spacing requirements (heat, airflow, clearances).

-

Documentation for every electrical component is reviewed and followed exactly.

-

If a part isn't UL certified, the entire panel cannot carry the UL label.

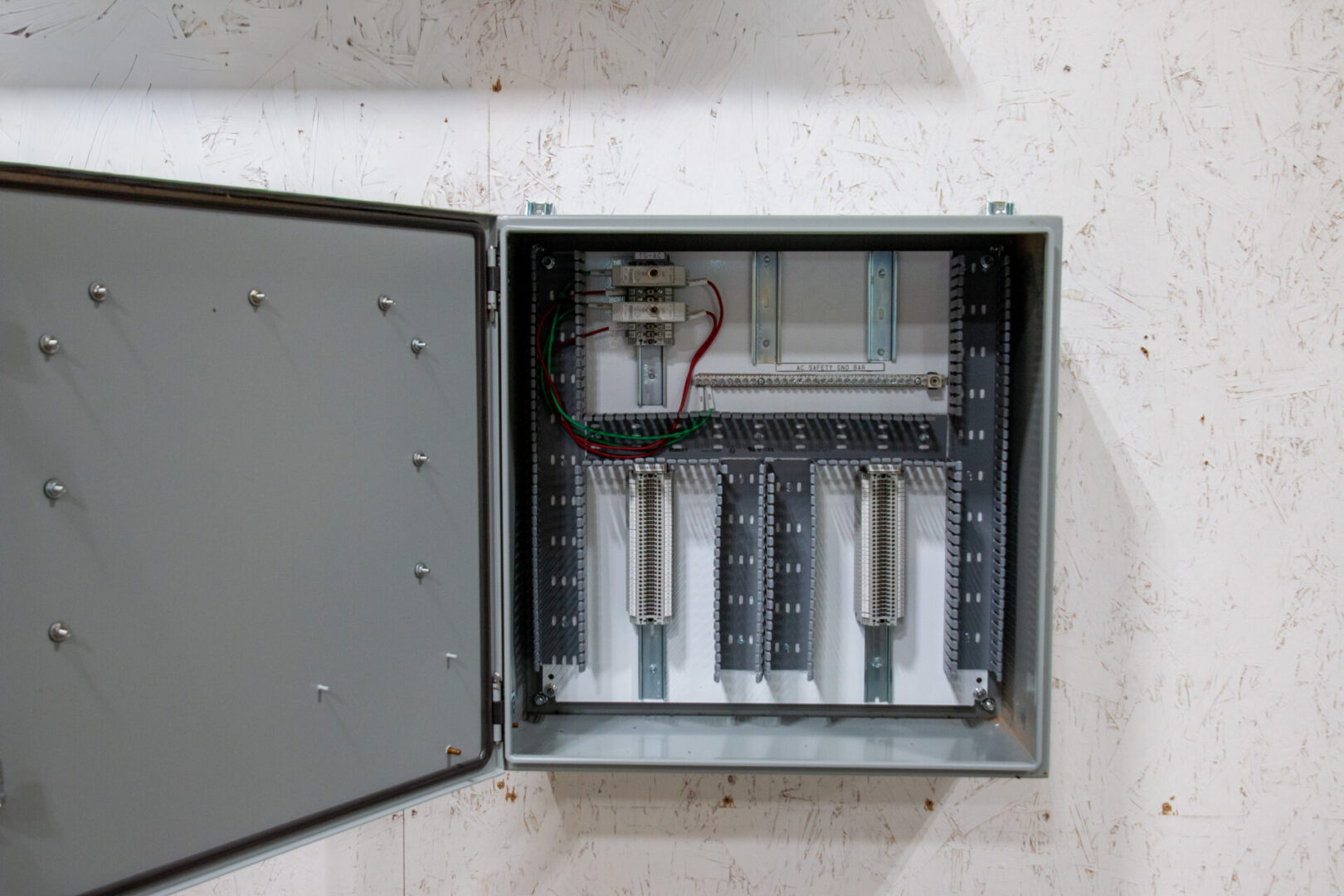

2. Panel Fabrication

-

Back panels are prepared with DIN rails, wireways, terminal blocks, and power supplies.

-

Enclosures are cut for HMIs, selector switches, pushbuttons, and conduit entries.

-

Panels are assembled for clean wire routing and maintenance access.

Rob notes:

“Any UL listed electrical part comes with documentation, and you must follow it exactly or the panel cannot be UL recognized.”

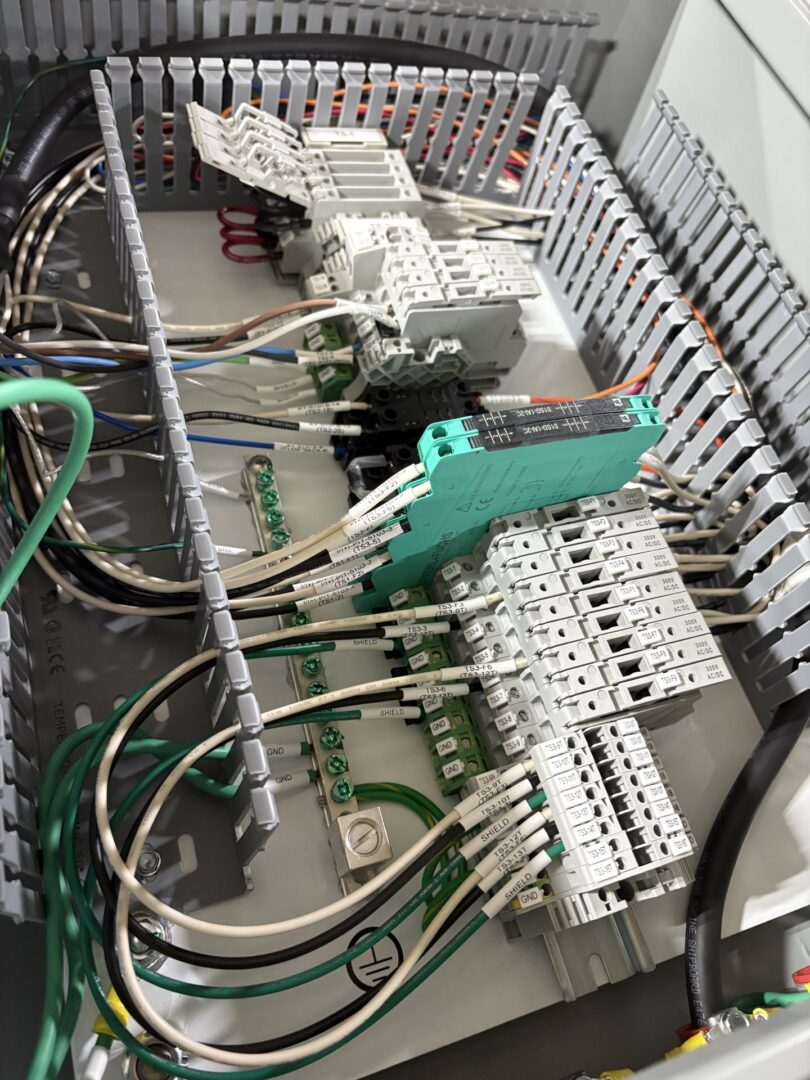

3. Wiring & Labeling

-

Every wire is labeled on both ends with origin and destination labels.

-

Every termination is torqued to specification to ensure circuit continuity.

-

All UL wiring, spacing, and labeling requirements are strictly enforced.

“Every wire must have a label on both sides. That’s crucial to keep people from making mistakes out in the field.”

4. Factory Acceptance Testing (FAT)

- Panels undergo comprehensive testing with power applied.

- Any wiring or component issues are corrected before shipment.

- UL label is applied after inspection requirements are met.

Rob explains:

“The FAT test will scream at us if something isn’t right. That’s how we ensure the panel is built correctly before it ships.”

5. Documentation & Shipping

-

Every panel ships with:

-

UL certification details

-

Component documentation

-

Corrected or redlined drawings

-

FAT results

-

Field installation drawings

“The customer gets the documentation for every part in the panel and the FAT test results. Everything they need for installation.”

-

SPECIALTIES

Our UL Certified Panel Shop Builds Panels for Extreme Environments

UL508A Control Panels

For oilfield sites, pump controls, industrial systems, and municipal facilities.

UL698A / Class I Div 2 Hazardous Location Panels

Built for environments with intermittent explosive gases.

Rob describes the importance:

“Class I Div 2 means gases can be present. Even a vape coil could cause an explosion. These panels must meet strict UL 698A requirements to keep sites safe.”

COMMON PANEL TYPES WE BUILD

- Pump control panels (including regen-drive pump jack systems)

- PLC control panels

- SCADA interface panels

- Motor control panels

- Automation control cabinets

- ITBC/CTP wellhead control boxes (high-volume repetitive builds)

- Municipal water treatment panels

- VFD pump jack control panels

“A lot of these panels are cookie-cutter across well sites. Others are one-offs that take more engineering time. We build both every day.”

WHY CHOOSE DSI

Because Your Operation Deserves Panels That Perform in the Field, Not Just on the Shop Floor

With DSI, you get:

-

UL certified craftsmanship you can trust

-

Experienced technicians and shop supervisors

-

Faster turnaround because engineering, fabrication, automation, and field services work together

-

Panels built to survive extreme heat, cold, vibration, and weather

-

A partner who stands behind the work

Rob sums it up best:

“We bring all aspects of the game to the table, panel building, fabrication, and field services. If someone asks, ‘Can you do this?’ the answer is yes… and we can do everything else too.”

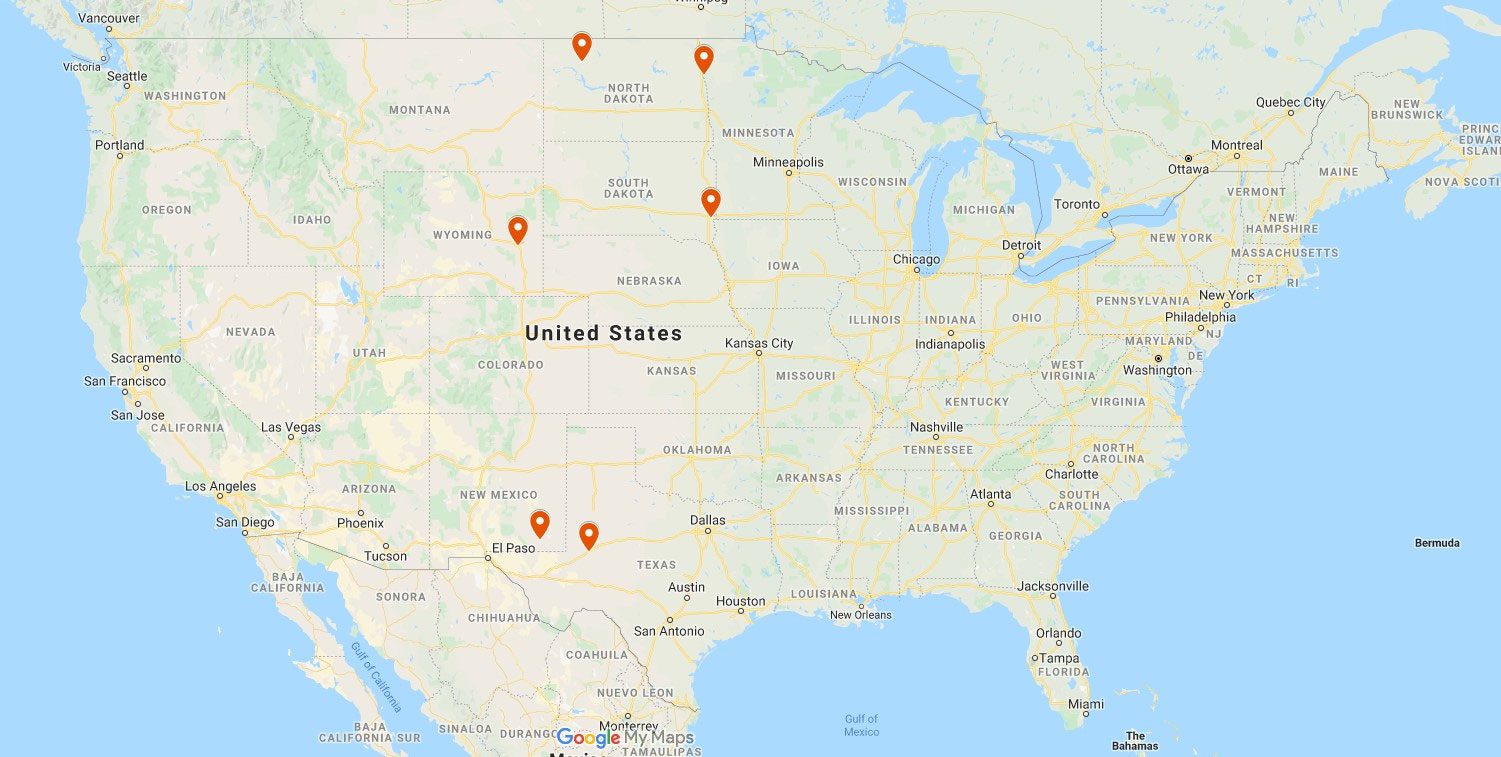

Where We Work

Permian Basin – Midland/Odessa

Supporting oilfield producers across West Texas and southeastern New Mexico.

Williston Basin – North Dakota & Eastern Montana

Providing electrical services for major operators across the Bakken.

DSI is strategically positioned in both regions to deliver fast mobilization and consistent workforce support.

Across The US

Our team travels well and we have teams working in many other areas of the US as projects arise.

Get a UL Certified Panel That Performs — Every Time, In Every Condition

Whether you need one engineered control panel or hundreds for oilfield deployment, DSI delivers quality, documentation, and reliability you can count on.