Modernizing Well Pads with Regenerative Drive Technology

Project Summary

Industry: Oil and Gas

Location: North Dakota – Bakken Formation

Client: Global Energy Company

Services Provided: Electrical Integration, Automation Engineering, Field Installation, Commissioning

Project Outcome:

Significant energy savings, reduced waste heat, improved uptime, and new mechanical insights across pump operations.

At a Glance:

-

130+ regenerative drives deployed

-

17% energy regeneration achieved

-

95% of regenerated energy reused

-

Projected $3M per month in energy savings at full rollout

The Client Challenge

-

A major global energy company operating in the Bakken faced mounting issues with aging motor control assets.

Many of their existing PowerFlex® 700 variable frequency drives had been in operation for 10+ years and relied on dynamic braking resistors to dissipate excess energy. This approach wasted power as heat and introduced unnecessary maintenance burdens.Additional pressures included:

-

Escalating energy costs

-

Utility grid constraints in the region

-

Corporate ESG commitments requiring reduced carbon footprint

-

Need for greater long-term reliability and scalability across hundreds of wells

The company needed a solution that could:

-

Improve efficiency and reduce power waste

-

Modernize decades-old technology

-

Support growth without requiring new grid capacity

-

Integrate seamlessly into their existing control architecture

DSI was selected as the partner to evaluate, engineer, install, and scale a next-generation solution.

-

DSI’s Approach: Design → Build → Integrate → Deliver

Design

DSI engineers collaborated with Rockwell Automation to evaluate available technologies, conducting a performance and compatibility analysis across the client’s field sites.

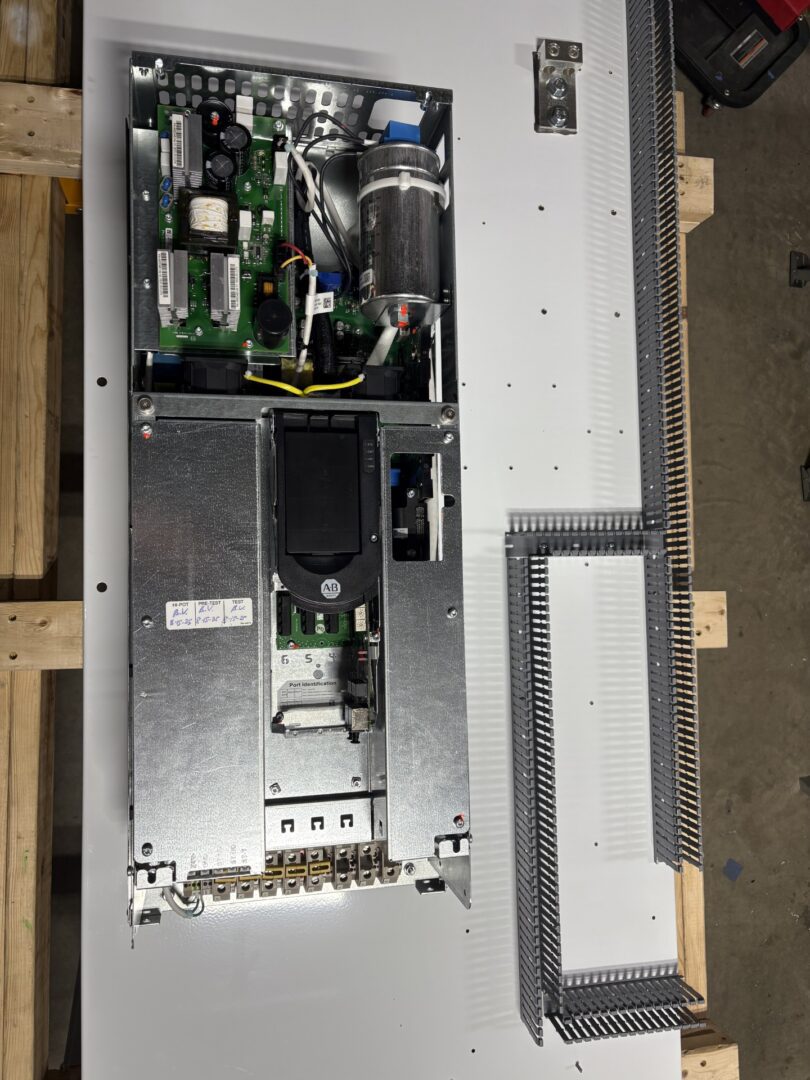

After reviewing multiple pathways, DSI recommended transitioning to PowerFlex® 755TR regenerative drives — a fully developed regen platform capable of reclaiming energy back into the system instead of wasting it through resistors.

Key engineering considerations:

-

Regeneration potential across typical pump rod duty cycles

-

Mechanical resonance tuning needs

-

Retrofit strategy for large-scale deployment

-

Compatibility with existing SCADA and field instrumentation

Integrate & Build

DSI and Rockwell personnel installed pilot units at three North Dakota well pads, wiring, commissioning, and tuning the systems to optimize performance.

During the test period, DSI collected data on:

-

Power consumption

-

Returned/regenerated energy

-

Torque accuracy

-

Production impacts

-

Drive tuning and resonance profiles

This real-world field data allowed DSI to fine-tune the approach before recommending full rollout.

Deliver

Once validated, DSI managed the multi-site deployment of over 130 regenerative drives.

The team ensured smooth transitions with:

-

Field installation teams working in coordinated waves

-

Drive parameter optimization

-

System documentation

-

Operator support

-

Maintenance handoff and future-phase planning

The Solution

-

The cornerstone of the modernization effort was deploying the PowerFlex® 755TR active front-end regenerative drive.

Key Performance Capabilities:

-

Returns excess power to the electrical system instead of producing heat

-

Improves mechanical behavior using adaptive control

-

Increases accuracy for pump torque and speed reporting

-

Reduces overall site power consumption

-

Supports scalability across hundreds of assets

As DSI President Casey Johnston stated:

“Rockwell leads the game right now in this active front-end regen drive, so it was an easy pick for us.”

-

Results & Impact

Substantial Energy Savings

With only 12% of the full rollout complete, the client already saw meaningful cost reductions.

At full deployment (1,200+ units), the project is projected to deliver:

-

$3M per month in energy savings

-

17% total regeneration, with 95% of that energy being reused

Improved Reliability & Production Insight

-

Adaptive drive control tuned out mechanical resonances automatically

-

More accurate torque and speed data improved well performance reporting

-

Reduced heat output improved drive lifespan

Carbon Credit Opportunity

Because the regen drives sharply reduce energy waste, the client can capture carbon credits — creating additional financial and ESG value.

Scalable Future-Ready Infrastructure

The new platform opens the door for advanced predictive maintenance using FactoryTalk® Analytics™ GuardianAI™, enabling future-condition monitoring for pumps and other equipment.

Why the Client Chose DSI

-

DSI’s value in this project reflects the company’s core strengths:

-

25+ years supporting America’s major oilfields (Bakken, Permian, etc.)

-

Deep expertise in automation, electrical, and integration systems

-

Long-standing Rockwell Automation partner

-

100% employee-owned team committed to quality and accountability

-

End-to-end services from engineering to field deployment

-

A collaborative, values-driven approach that aligns with leading energy operators

DSI is not just a contractor, we are a long-term partner helping energy companies modernize and prepare for the next decade of production innovation.

-

Ready to Modernize Your Field Operations?

Request a Technical Review

Our engineering team can evaluate your existing systems, and field infrastructure to identify modernization opportunities that improve efficiency, reliability, and safety.